In many CNC facilities, air nozzles are used to spray air over oil laden parts, or floors. In this process, oily aerosols are produced, which settle on the floor causing accidents. The aerosols are also inhaled by workers, causing many health problems. MiJET systems are used at facilities with CNC machines to clean oil, residues, and part chips. These industrial cleaning systems are powered by air, and provide various advantages over typical cleaning methods. Let’s see how the MiJET standalone cleaning system provides relief from health complications and workplace accidents at worksites.

6 Benefits of Using MiJET Systems

The following benefits describe how MiJET systems are becoming assets for complex industrial systems.

- Cleans Air and Cleans Machine Parts:The MiJET cleaner can be used to clean debris on machine parts. It can be used to clean fluid drops, and articulates. The atomized particles in the air are captured in the suction pump. Thus, there are very few chances of them settling on the floor, or clogging the plant’s air filtering equipment. Also, workers are less likely to inhale the aerosol mist because it is pulled and captured in the container via suction.

- Aids in Recycling Lubricants and Scraps: All debris are captured in the bucket. The bucket can be detached, and debris can be segregated easily. Expensive coolants can be reused. Scraps and chips can be easily recovered.

- Eco-friendly: The MiJET is driven by compressed air, and no electricity is needed. It can be easily connected to any air line in the shop using FNPT 1/4ʺ fitting.

- Helps Promote Safe Shop Environment: The cleaning system helps to promote a safe shop environment. Aerosol mist and atomized particles are two major pollutants in facilities with CNC machines. These are captured by the cleaning system easily. Floors are cleaner, and slick free.

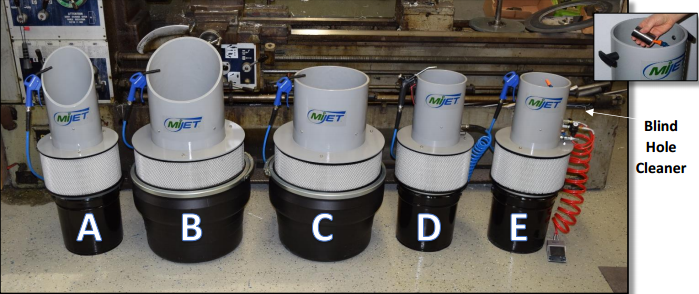

- Portable Design: The MiJET has a self-contained and portable design. It can be used near any machine, equipment, or inspection station, where parts and floors need to be cleaned regularly. It can be used at any location, where air lines are available.

- Ideal for Various Industrial Applications: The MiJet is not only ideal for oily CNC facilities, but can be employed by automotive manufacturing units, injection molding services, job shops, commercial food preparation units, furniture manufacturing shops, automotive garages, etc.

Today, there is a huge demand for eco-friendly cleaning systems. MiJET is one such system, which meets application requirements, as well as expectations of customers. Techna Tool is one of the major suppliers of MiJET systems in the USA. The organization provides reliable tools and process monitoring systems for its clients in various industrial segments.