Tool monitoring is an essential process when it comes to machining systems. There are a number of reasons for this: they help to manage resources; help in terms of overall system evaluation and maintenance; they can also be usedto make decisions that can improve overall system performance and shut down the line to prevent bad parts or scrap from being manufactured.

However,with numerous industries having specialized monitoring needs, you need a manufacturer that can provide solutions to unique requirements. Techna-Tool Inc. can provide the required solution with one-of-a-kind and effective contact and non-contact monitoring systems.

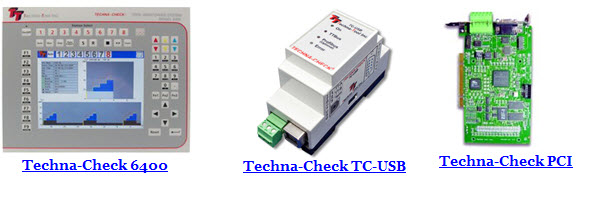

Tool Monitoring System Solutions

Techna-Tool Inc. offers different types of monitoring systems that can meet unique industrial needs.All of Techna-Tool’s systems are designed for the detection of worn, broken, and missing tools.

- Techna-Check 6400: This unit is preferable for small to medium sized industrial systems. The TC6400 can monitor up to 8 different motors as well as 64 types of tools and cutting paths. The unit consists of an 8″ color display as well as a membrane keyboard, allowing for easy data input. The operator can directly input the required parameters into the system, and can take into account various monitoring scenarios.

- Techna-Check TC-USB& PCI Systems: The TC-USB& PCI systems utilize the TTMON software which is designed to meet the needs of large scale production systems. A single system can monitor over 20 different machines and 128 cutting tools. It consists of a USB or PCI interface, which allows for quick and easy computer connections. Independent limits can be created for supervision of idle, blunt,broken, and missing tools. The system can also interface with an accelerometer to measure vibrations on spindles or fixtures.

As you can see, Techna-Tool provides tool monitoring systems that can meet the requirements of various sized industrial applications.