The TC-USB interfaces to the machine control using 24vdc I/O or Profibus. A single TC-USB unit can monitor up to 20 different motors/machines and each machine can have 128 different tools or cutting paths monitored. The tool selection is done using binary inputs through the I/O100T module which are typically given from M-codes/Marco I/O or by using Profibus without the I/O100T.

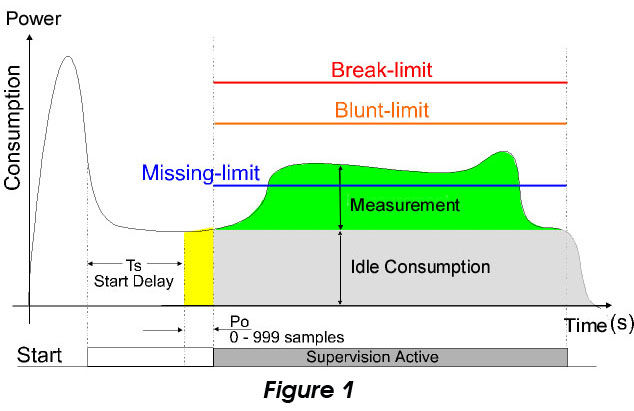

Once the unit has been told to monitor, the system will measure the power that is used just to turn the spindle; this is labeled as the idle consumption (figure 1). High and low limits can be set for the idle power to determine if a belt has broken or bearings are going bad in the spindle.

The unit then learns the amount of power it takes to cut the material (labeled as measurement in figure 1). As a tool becomes blunt (dull) the tool will begin to require more power to complete a machining cycle. When the tool breaks a short energy peak or spike is created and if no tool is present or the part has already been cut, the power consumption drops back to zero. If any of these situations occur the Techna-Check will output a fault which immediately stops the machine.

Each of the 128 possible cuts has a unique set of parameters associated with it allowing for various monitoring scenarios. Limits can be set based off the peaks of the profile or off the area under the curve. Typically a tools parameters can be set after just a few machining cycles making the system very easy to use and quick to setup.

The Techna-Check® model TCPCI120 is a Tool Monitoring system designed to use our PWM-TTBUS series power transducers to measure true power on a machine spindle or axis motor. It can be used on standard motors, AC servo motors and variable frequency drives. The Techna-Check determines if there is a Broken, Dull or Missing tool. The system also has the capability to interface with an accelerometer to measure vibration on a spindle or fixture and verify it is within a set range.

The PCI interfaces to the machine control using 24vdc I/O or Profibus. One PCI card can monitor up to 20 different motors/machines and each machine can have 128 different tools or cutting paths monitored. The tool selection is done using binary inputs which are typically given from M-codes/Marco I/O or by using Profibus.

Once the unit has been told to monitor, the system will measure the power that is used just to turn the spindle; this is labeled as the idle consumption (figure 1). High and low limits can be set for the idle power to determine if a belt has broken or bearings are going bad in the spindle.

The unit then learns the amount of power it takes to cut the material (labeled as measurement in figure 1). As a tool becomes blunt (dull) the tool will begin to require more power to complete a machining cycle. When the tool breaks a short energy peak or spike is created and if no tool is present or the part has already been cut, the power consumption drops back to zero. If any of these situations occur the Techna-Check will output a fault which immediately stops the machine.

Each of the 128 possible cuts has a unique set of parameters associated with it allowing for various monitoring scenarios. Limits can be set based off the peaks of the profile or off the area under the curve. Typically a tools parameters can be set after just a few machining cycles making the system very easy to use and quick to setup.