PWM3110T Load Transducer

Load Transducer for 1- or 3-phase AC Loads

An ultra-fast and precise measurement transducer specifically developed for Machine Tool Monitoring applications. The PWM3110T is a unique design based on the fastest available 32 bit Microcontroller and 18 bit successive approximation AD Converters. A sampling rate of 150kHz ensure precise and correct measurement even when used with Frequency Inverters with 20kHz PWM base frequencies and higher.

PWM3110T measures true motor power [kW].

· TTBus Output

Proprietary RS485 type Sensor Bus

· 13 Programmable Measurement Ranges

0.01, 0.025, 0.05, 0.1, 0.25, 0.5, 1, 2.5, 5, 10, 25, 50 or 100%

· Hall Sensors

200 Amp, 500 Amp. or 1000 Amp available

Technical Specification

Mechanical

Housing: Polycarbonate.

Mounting: 35 mm DIN-rail.

Protection Class: IP40.

Temp. Range: -15 to + 50 C.

Weight: App. 200g.

Dimensions: 120 x 23, 5 x 113 mm.

Electrical

Voltage Input: 3 x 0-500 VAC/VDC max.

Current Input: 3 x 200/500/1000 A, 0 Hz - 60 kHz

Power Range: 160, 398 or 797 kW at 460 VAC.

Supply: 18-36 V DC max. 4.0 Watt.

TTbus output: RS485 - proprietary protocol.

Features

· The PWM3110T is designed primarily for measuring AC power delivered to motors driven by Variable Frequency Inverters.

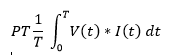

AC power is measured from the formula:

Where: T = period, V (t) = voltage and I(t) = current.

Where: T = period, V (t) = voltage and I(t) = current.

· The PWM3110T Power or Current Transducer is specifically developed to function as a load transducer for the

TECHNA-CHECK® Range of Machine Tool Monitors.

· A Power Transducer for Tool-Monitoring must be fast and accurate. Sometime the measurement speed is as high as one half period, unlike commercial power-meters, which measure power averaged over several seconds.

· Please note that most commercial Power Meters will not even be able to measure Power correctly after a Variable Frequency Inverter. The transducer interfaces to Tool Monitor Applications via the proprietary TTBus interface.

· The three motor wires must pass through the external hall sensors in the same direction to the motor either from Top- Bottom or from Bottom-Up.

See Brochure

PWM3110T Load Transducer

Additional Information :