It is hard to argue that horizontal machining centers are the work horses of the machining industry. Known for their repeatable production abilities, they are relied upon around the clock by manufacturers world-wide. While high volume creates great opportunity, broken tool monitoring is utilized to prevent faulty work pieces, material waste, and production down time.

Techna-Tool is a worldwide leader in monitoring system supply, development, and service. Let’s look at a few common asked questions regarding broken tool detection on horizontal machining centers:

How Much Volume is Necessary for Broken Tool Monitoring?

Adding tool monitoring typically makes sense when one or more aspects of the machining process are fully or partially automated. With the high price of horizontal machining centers and high cost of waste or down time, it does not take long to achieve payback on tool monitoring equipment.

Optic Based or Contact Monitoring?

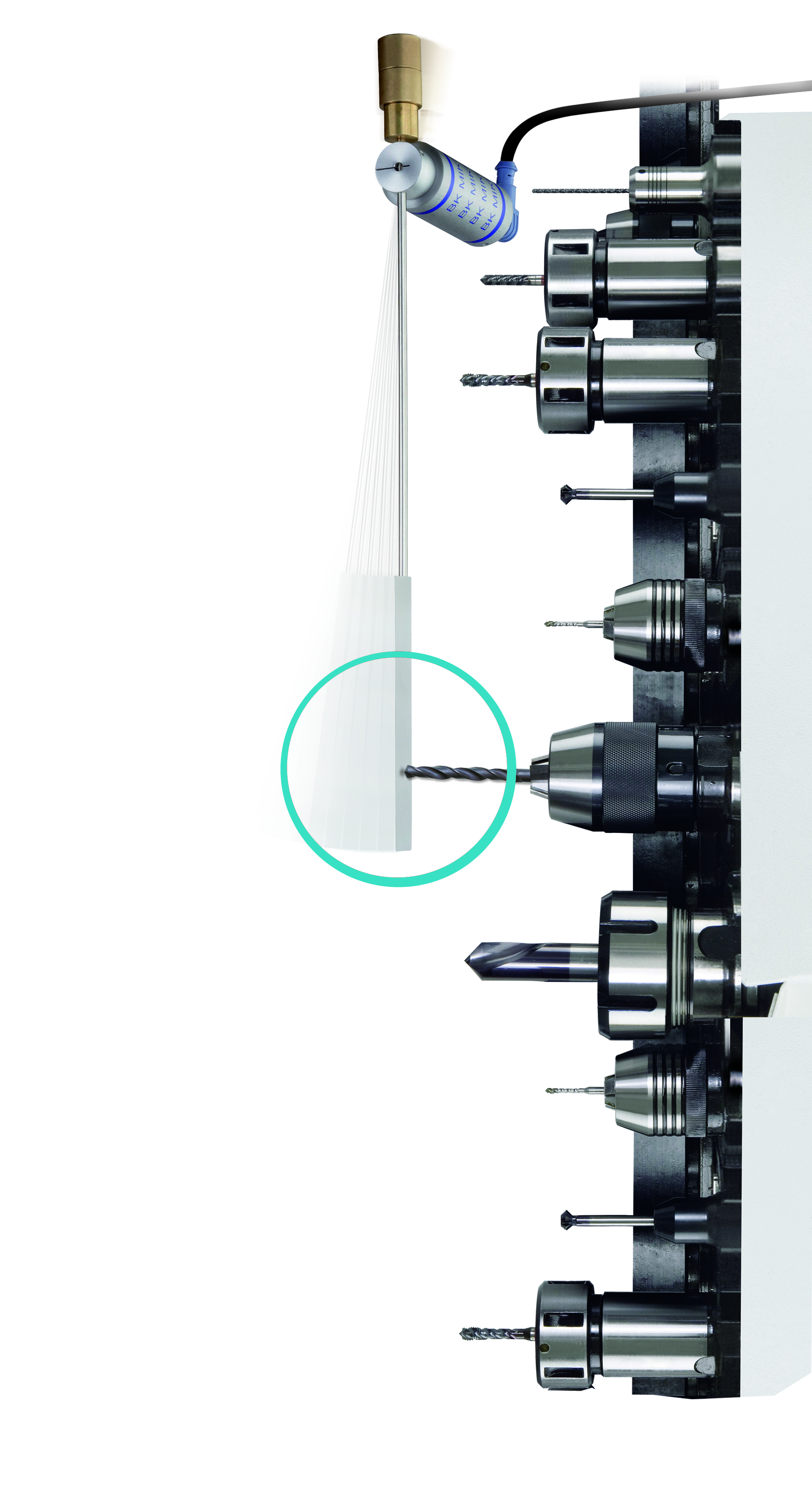

Machinists seem to have an affinity towards systems featuring lasers until a laser system is installed. Despite advances in air purging cleaning technology and camera-like shutters to prevent debris issues, optic based systems need maintenance. Techna-Tool has dedicated its efforts towards maintenance free, learned position, contact monitoring with the BK Mikro line. For advanced process monitoring, the Techna-Check system monitors power usage profiles.

How Much Cycle Time Does Broken Tool Monitoring Add?

While the answer to this question varies by monitoring product provided, Techna-Tool’s products typically do not add cycle time. BK Mikro monitoring typically check tools immediately after use within the tool changer. The Techna-Check power monitoring gathers data directly from the process from its sensors.

How Small of a Tool Can Be Monitored Through Contact?

The BK Mikro line learns the exact location of the tool and can rapidly decelerate to monitor tools only thousandths of an inch in diameter. This monitoring system is popular in Swiss-style machining.

What are Other Uses of Tool Monitoring?

The BK Mikro line provides solutions to check tools from the side using the standard wand, from the tip using the wand/paddle, and even a linear probe application to check hole locations and size. This useful system flexibility allows systems to be used in a variety of applications beyond tool breakage including inspecting part position, alignment, feeding, ejection, presence, drill depth, cavities, profile and tolerance.

Is a Warranty s Provided?

Techna-Tool provides a three year warranty on its tool monitoring systems.

Please visit www.techna-tool.com for more information.