Manufacturers are constantly seeking ways to succeed in challenging industrial landscape. One of the best ways to achieve this is by staying on top of trends and embracing the right technologies at the right time. Attending industry-specific events becomes not just a choice but a strategic imperative to meet this goal. Are you looking forward to an event that appeals to manufacturers, allows you to explore cutting-edge technology, and find creative solutions for your manufacturing challenges? If that answer is yes, your wait is over because the Wisconsin Manufacturing & Technology Show (WIMTS) 2023 is only a few days away. This event will be held on October 3, 4, and 5, 2023, at the Exposition Center at Wisconsin State Fair Park in West Allis. You can meet the experts from Techna-Tool at booth number 845. To give you a detailed idea, this post will help you understand how this event promises to be a game-changer for the manufacturing industry and what you can expect at the Techna-Tool booth.

7 Reasons Why You Should Attend WIMTS 2023

The event is going to be an incredible showcase of the latest advancements in the manufacturing industry. Let’s check some of the perks of attending this event.

- WIMTS is the premier Midwest manufacturing trade event, showcasing a wide range of technology-driven equipment in robotics, machining centers, welding, tooling, and fabrication equipment.

- This event appeals to everyone in the manufacturing sector. Whether it be a local machining shop serving local customers or a seasoned manufacturing company serving international markets, both may be equally interested in learning how to succeed in their business with minimal effort.

- The event is set up at the Wisconsin State Fair Park’s 100,000+ square foot Exposition Center and more than 3,500 people and 200+ exhibitors are set to attend WIMTS this year.

- This is a golden opportunity to get close and personal with technology suppliers serving aerospace, automotive, mining, medical device manufacturing, and agriculture markets.

- Connecting with like-minded professionals and industry leaders can turn into long-term business partnerships at WIMTS, which can help you in expanding your professional network.

- WIMTS will be an ideal place to see live demonstrations and interactive displays with the latest innovations in CNC machine tools and learn about the latest innovative machinery and technology that will give you a deeper understanding of their benefits in your manufacturing process.

- This event will help you evaluate while making informed decisions and discuss applications with a variety of vendors and industry experts all in one location.

Why Stop by the Techna-Tool Booth at Booth 845 at WIMTS 2023?

Techna-Tool has exhibited at WIMTS for several years. The following reasons will make you stop at 845 at WIMTS 2023.

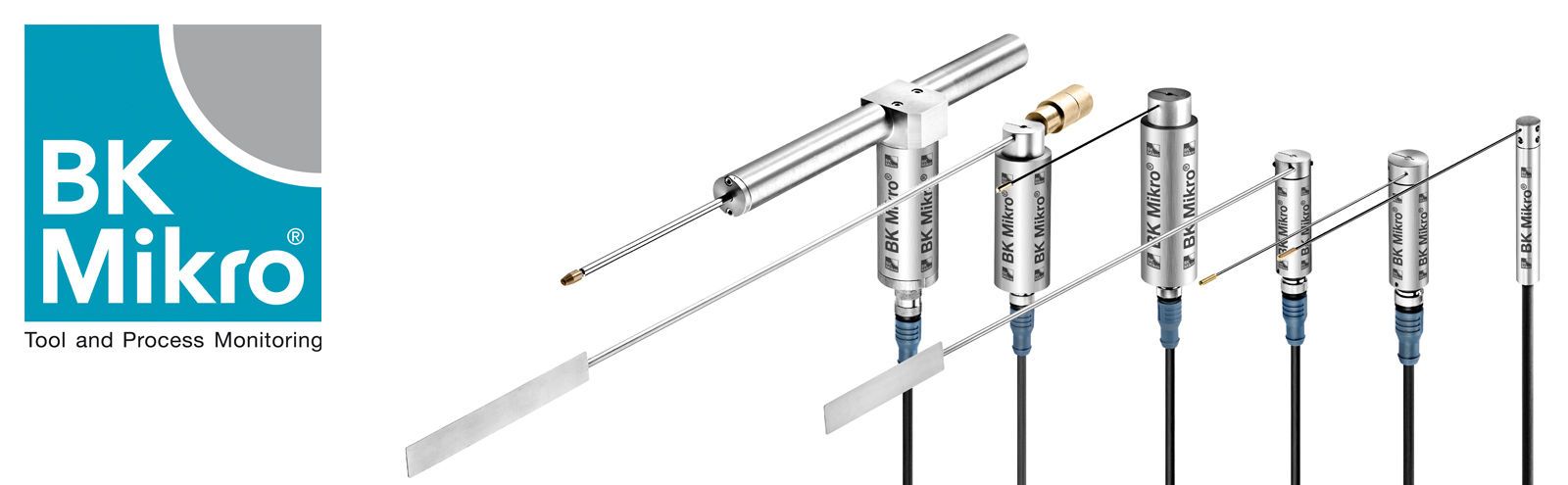

- This year, the attendees can see the popular tools and production monitoring systems from Techna-Tool, such as BK Mikro and Techna-Check.

- These systems are successfully used across manufacturing facilities to monitor tools and processes.

- You can discuss your production bottlenecks with the experts from Techna-Tool and they will help you find the right solution.

Do you want to make an appointment with one of our experts before other attendees flock to the Techna-Tool booth? If so, click here to fill out the form to schedule a meeting with Techna-Tool experts.

WIMTS 2023 Schedule At-A-Glance

Here’s a quick glance at the WIMTS 2023 schedule.

Event Details:

Wisconsin State Fair Park – West Allis, WI

Date: October 3-5, 2023,

Time: 9 am – 4 pm.