Machine and tool detection systems are now an important part of machine health and production monitoring systems. They help manufacturers optimize production volumes and eliminate unwanted downtimes by recording data in real-time and analyzing it. This is done using certain probes that are integrated with the software. These tools detect not only broken tools but also check defective parts, perform an inspection of objects as well position recognition. BK Mikro scanner is a type of tool and process monitoring system that helps in detecting tool breakage through the process of scanning. It is also used for other industrial applications, including position recognition, checking part defects, object inspection, and so on. Techna Tool offers different variants of BK Mikro scanners for multiple industrial applications. Are you intrigued to know more about these scanners? If yes, read the post below. This post offers you a brief overview of BK Mikro scanners and their variants.

An Overview of BK Mikro Scanners

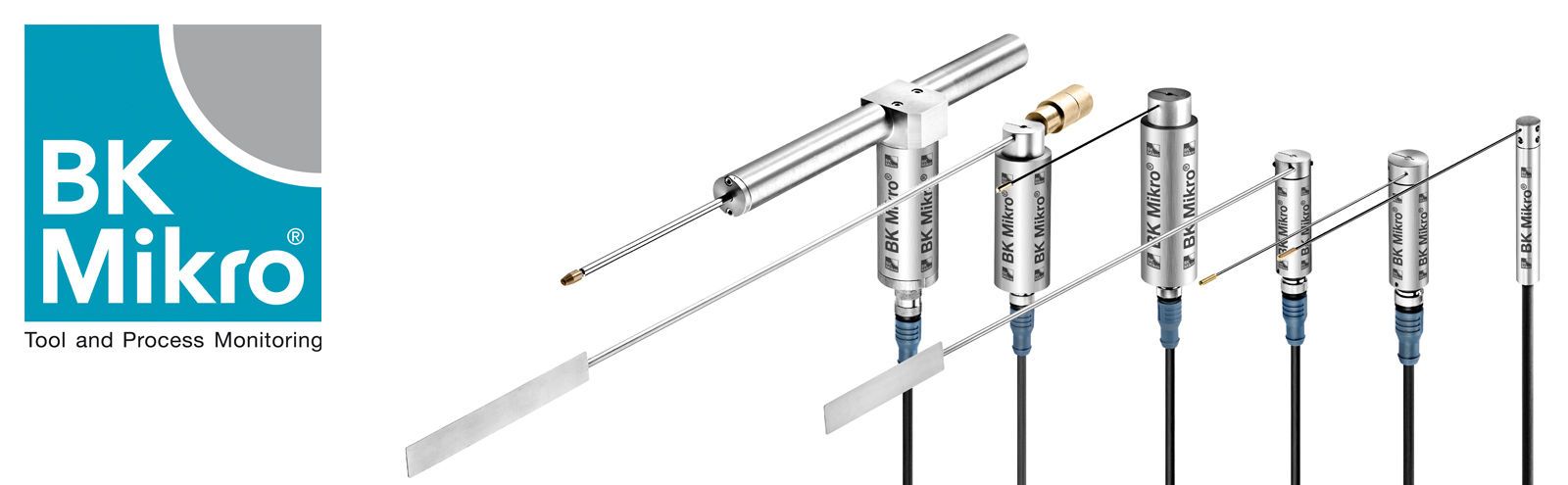

BK Mikro scanners are flexible devices for tool and process monitoring. It is also used for object and free space monitoring applications. These scanning tools are chips and coolant resistant and easy to maintain. These scanner systems comprise an encoder and a servo motor that allows you to check the tool position through a probe. The tool position is memorized by the scanner and is later used to verify whether the tool is in the same condition. If the probe notices any difference in the tool position, the scanner generates a signal which tells the operator that the tool is broken. The operators can immediately analyze and fix the breakage, thus eliminating further loss and production downtime.

Variants of BK Mikro Scanners

The following are the variants of BK Mikro scanners, each consisting of unique features:

- TK7 A/RL: TK7 A and TK7 RL possess similar features. The only difference between the two is that TK7 A has a mechanical stop within the device that stops the scanner movement. In contrast, the TK7 RL variant rotates in both directions without stopping. These variants of BK Mikro scanners are ideal for tight tool spaces where large scanners cannot fit.

- TK91 A: This variant is suitable for detecting tool breakage within the tool changers. It has the capacity to store 512 different tool lengths in memory. It can check tools with lengths up to 22 inches and has a tolerance range from 0.05 to 25.4 degrees.

- TK9LIN50: TK9LIN50 is a scanner that comes with a 50mm stroke with a pinion and rack for probing. This variant offers accuracy up to +/- 0.05mm and can monitor specific distances with longitudinal scanning. It is ideally used for applications where rotary scanning is prohibited.

- TK96: This is one of the most compact variants of BK Mikro scanners. It has a stainless steel body that makes it wear and debris resistant. In addition, it comes with a diameter of only 12mm and therefore is ideal for tools with tight spaces.

- TK94 A/RL: TK94 A and TK94 RL variants come with similar features. The only difference between these two variants is TK94 A can be used in free space or single positions, while TK94 RL can be used in multiple directions without stopping. These scanner variants are suitable for harsh industrial environments as they are built with robust scanning motors.

After reading the information above, you may have got some clarity on BK Mikro scanners in tool and product monitoring applications offered by Techna Tool. If you are an OEM and wish to enhance your production efficiency by identifying broken tools on time, then you must invest in BK Mikro Scanners. These devices will take your industrial production to the next level with precision. Techna Tool is one of those reliable and established players offering these systems. The company offers high-quality variants of BK Mikro scanners. In case you come across any queries, please get in touch with the team at Techna Tool today. They will guide you with the product details and the buying process.