No matter how many new innovations and efficiencies you put into the automated production of a part, the machining process is always going to be involved. In other words, with today’s technology, the speed with which a standard component can be built has little to do with the complexity that goes into building it. The various operations that “eliminate” human error on a transfer line are still eventually prone to wear-out, breakdown, and failure. What, then, is a company to do to maintain the timeliness and quality of its production process, when even automated operations are prone to malfunction and breakage? If GM or Ford, for instance, is building an engine block for an automobile and is reliant on a process that (for the most part) is not under human supervision, what happens when an unwatched system malfunctions suddenly and there’s no-one to see it? The answer lies in finding a technology that keeps track of each operation’s proper functioning. That’s where our BK Mikro comes into play.

If GM or Ford, for instance, is building an engine block for an automobile and is reliant on a process that (for the most part) is not under human supervision, what happens when an unwatched system malfunctions suddenly and there’s no-one to see it? The answer lies in finding a technology that keeps track of each operation’s proper functioning. That’s where our BK Mikro comes into play.

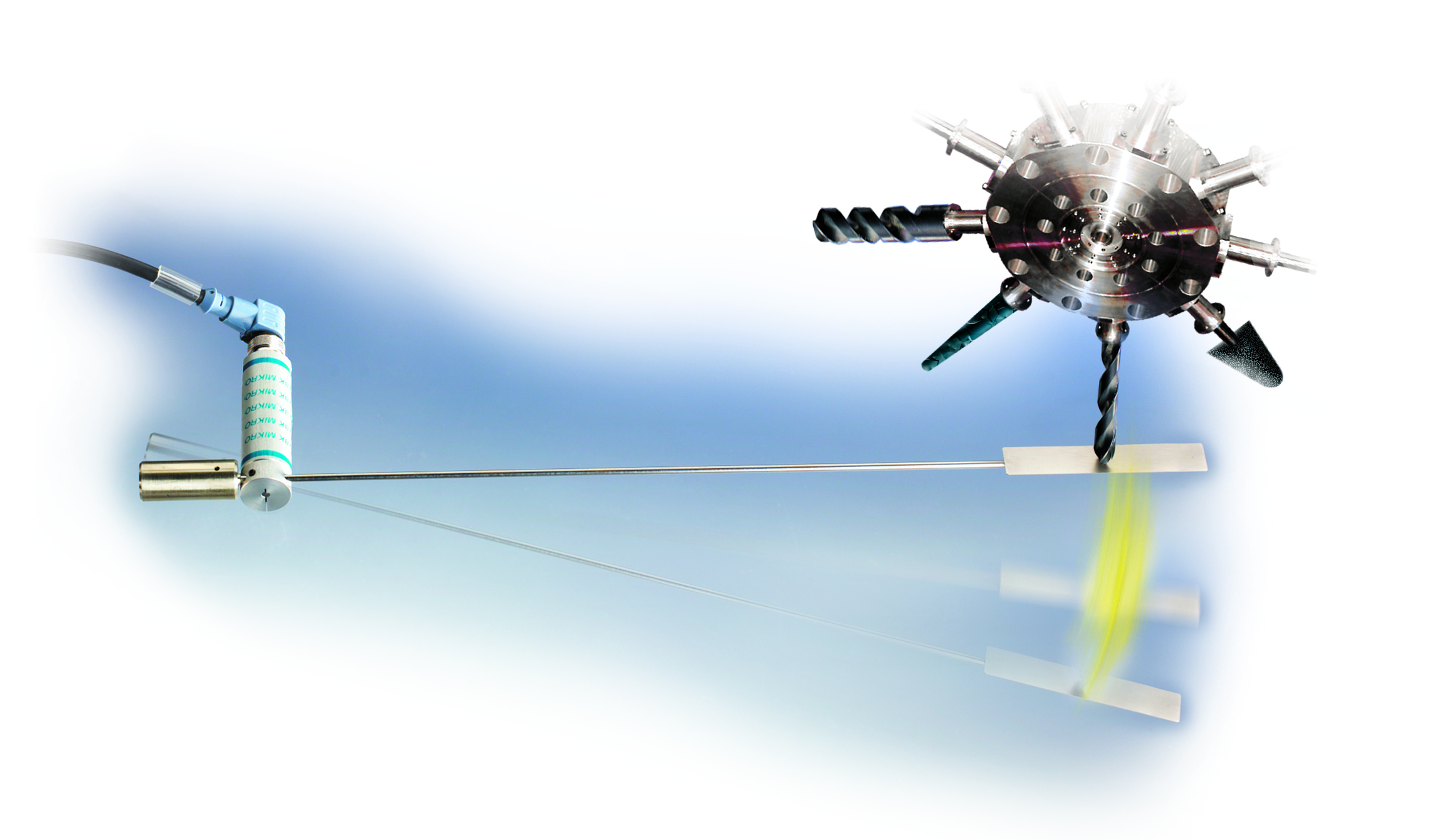

The BK Mikro is Techna-Tool’s unique solution to the problem of effective monitoring of line machinery. Once installed, the BK Mikro verifies tool presence after each machining cycle. If a broken tool were to occur, the BK Mikro sends signal to the machine control which stops the machine immediately. It’s a straightforward solution to a complex problem.

With the BK Mikro monitoring a factory’s automated tools, the need to manually spot flaws in the production process is taken out of the equation. The fact that the BK Mikro can shut down the transfer line in question ensures that no necessary machining features are missing at line’s end.  In addition, since the BK Mikro identifies which precise operation is no longer functioning properly, it eliminates need to rework parts which may have slipped past the station, if the BK Mikro hadn’t stopped the machine.

In addition, since the BK Mikro identifies which precise operation is no longer functioning properly, it eliminates need to rework parts which may have slipped past the station, if the BK Mikro hadn’t stopped the machine.

Our BK Mikro is one of the chief means by which thousands of industrial operations are effectively monitored, including some of the largest industrial companies in the world. Techna-Tool is proud to have our technology employed in various GM and Ford machining plants across the United States. From the GM plants at Tonawanda, NY and Romulus, MI to the Ford plants at Sharonville, OH, the foremost leaders in the automotive industry depend on our technology to keep their machines running properly.